Not all DIY builds work first time, but with a little patience and some investigation you may be able to debug your build yourself.

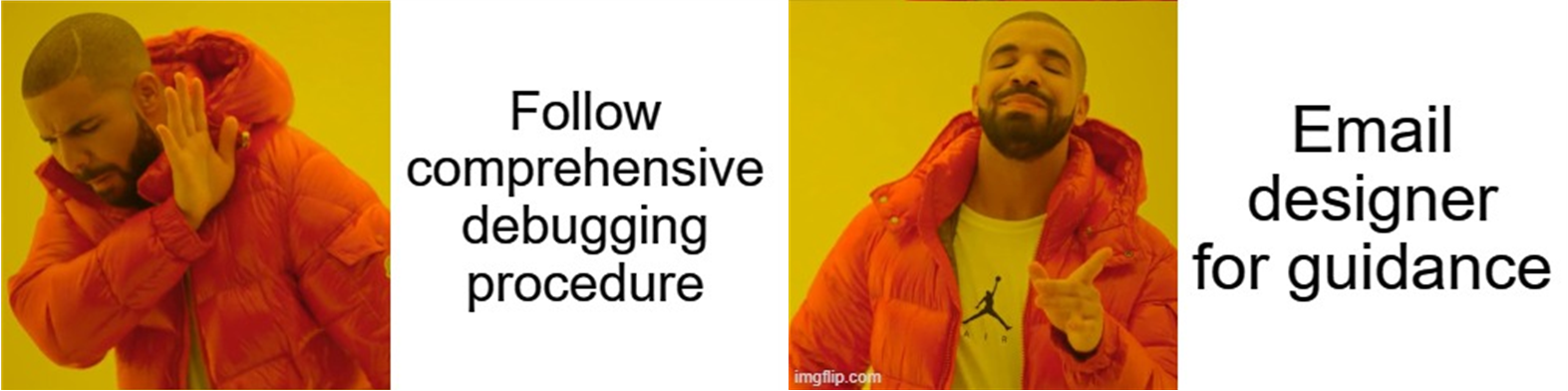

There is no silver bullet, it’s down to following a process with a good dollop of perseverance. It’s worthwhile exercising a little humility, and accepting that you may have made an error, rather than emailing FC to ask us why your build doesn’t work.

Here are the steps that you should take:

The vast majority of build issues are down to soldering inconsistencies. This is far more likely than a bad IC, for example. The first step of successful troubleshooting should always be to reflow all soldering to eliminate any dry joints (bad connections) or solder bridges (short circuits). This is also an opportunity to closely inspect your work – you might find some unsoldered pads, or an IC not inserted into its socket, for example. Next steps are to double check all resistor values are correct, and to check polarities of all diodes, transistors, ICs and electrolytic capacitors.

Eyes ARE NOT multimeters! You cannot ‘look over’ your soldering. It DOES NOT ‘look okay’. You need to REFLOW that lead(free).

List of what YOU CAN use your eyes for:

– gaze upon the awesomeness of FC modules

– look on in wonder at FC YouTube videos

– peruse the FC website

List of what YOU CANNOT use your eyes for:

– check continuity

– detect all dry joints

– detect all solder bridges

99% of DIY build issues are down to soldering issues. Do the World a favour and REFLOW.That is all!

*If you are Borg and your eyes do actually function as multimeters please ignore this public service announcement.